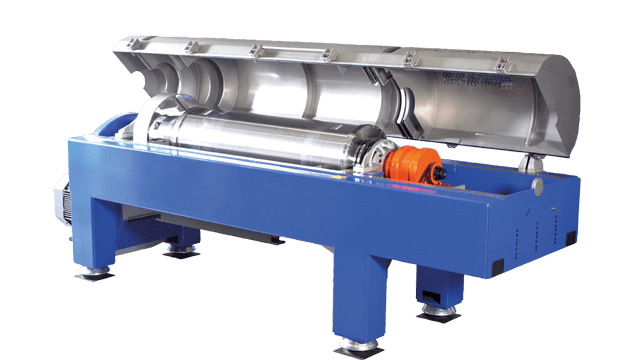

PANX

Alfa Laval PANX palm oil decanter centrifuges are designed for oil clarification and purification. The palm oil decanter centrifuge offers maximum oil recovery from sludge underflow or empty fruit bunch liquor with low energy consumption, excellent solid dryness and high-quality separation. The PANX is a proven decanter for the processing of crude palm oil and is well suited for the heavy duty and tough environment of the application.

The highly efficient palm oil decanter comes with the following benefits:

- Higher yield as you reduce palm oil loss with maximum oil recovery from sludge

- Low power consumption thanks to an innovative liquid outlet power tubes design (up to 30% lower than with conventional outlet design)

- Improved separation of palm oil in a cost-efficient way

- Improved solids dryness, leading to lower costs for drying or disposal

- Increased capacity with same or less space requirement, for a smaller investment

The high-performance three-phase decanters are purposely designed for processing crude palm oil, with oil loss reduction rate surpassing industry acceptable limits. Critical parts of the industrial decanter are made from wear resistant material, making it durable and low-maintenance. With a compact, modular and automatic Cleaning-In-Place (CIP) design, these oil decanter centrifuges offer efficient non-stop operation, reliable separation of liquid, dry solids (cake) and oil whilst saving space. Our smart automatic control system and special power tube design provides easy optimization.

Range

The PANX solid bowl centrifuge range includes low, medium and high capacity decanters suitable for oil mills from 30 to approximately 90 tons of fresh fruit bunches (FFB) per hour.

Applications

- Oil recovery from sludge underflow

- Oil recovery from empty fruit bunch liquor

- Desludging of anaerobic effluent ponds

Ban Dung palm oil industries impressed with the Alfa Laval PANX 800

The Alfa Laval PANX 800 is a cumulation of decades of innovation and breakthrough by the Alfa Laval R&D team. This high capacity and high performance decanter is now ready to meet the needs of the palm oil industry.

Meet the new PANX 800

With the introduction of Alfa Laval's new palm oil decanter centrifuge model, PANX 800, the PANX range is now suitable for every size of palm oil mill, from 30 to approximately 90 tons of fresh fruit bunches (FFB) per hour, and for a variety of crude palm oil applications.

How it works

How the PANX Palm Oil Decanter works

Whatever the application, Alfa Laval PANX decanters work according to the same basic principles.

The separation of either pressed palm oil, sludge from settling tanks or empty fruit bunch liquor into dry solids (cake), mill effluent (water) and recovered oil fractions takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The palm oil product is fed into the bowl via a new inlet feed zone which provides effective and gentle acceleration resulting in less emulsions created and no tendency for plug up. Centrifugal force causes instant sedimentation of the dry solids on the wall of the bowl, and the liquid phases – heavy phase (water) and light phase (oil) – separate in layers. The conveyor, rotating in the same direction as the bowl but at a different speed, moves the solids to the conical end of the decanter. Here, the solids are lifted clear of the liquid and centrifugally dewatered before discharge into the collecting vessel. The clarified liquids overflow into the decanter’s casing through an opening in the cylindrical end of the bowl. Both phases leave the collecting compartments in the hood by gravity flow through outlets under the machine.

Innovative liquid outlet design

In Alfa Laval PANX decanters an innovative liquid outlet design reduces power consumption (up to 30% lower than with conventional outlet design). The Basic Control System, makes it easy to upscale and downscale capacity.

Drive system

In all Alfa Laval PANX three-phase decanters the bowl is driven towards the conical end piece by an electric motor and V-belt transmission. Power is transferred to the conveyor via a planetary gearbox.

The speed difference is controlled in different ways, depending on the decanter type:

- Alfa Laval PANX CS decanters feature a countershaft transmission, where pulleys can be changed manually to optimize the differential speed

- Alfa Laval PANX VFD decanters are equipped with an automatic back drive system for the main motor. By measuring torque the VFD system optimizes the differential speed without changing belts or pulleys for an overall reduction of the power consumption.

Control systems – process optimization with Basic Control System

Alfa Laval PANX decanters with variable frequency drive (VFD) are delivered with the automatic Basic Control System. This control package is capable of fully controlling the decanter operation, including liquid clarification, solid dryness level, adjustment of process differential speed, automatic solid load and feed of incoming material.

The Basic Control System ensures efficient performance and keeps the cost for installation, commissioning, operation and maintenance to a minimum. It is also designed to measure bearing temperature and to monitor the vibration levels.

Alfa Laval PANX decanters with Basic Control System can be adjusted to suit specific process requirements by varying:

- Bowl speed to obtain the G-force required for the most efficient separation

- Pond depth in the bowl for optimum balance between liquid and oil clarification, while at the same time optimizing the solids dryness

- Conveyor speed for most efficient balance to ensure minimum wear from abrasive solids

- Feed rate to handle a wide range of different flows when operating on various types of solids and oil contents.

Alfa Laval PANX CS decanters that have countershaft transmission are equipped with the Star-delta start-up system as standard.

Service

Extending the performance of your equipment

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Maximize operating reliability with Alfa Laval IoT Services

Alfa Laval’s IoT Services is a range of digital services that maximizes operating reliability and uptime in food & beverage processing plants.